Toledo Residents - Learn Lean Six Sigma’s History Here

Contact Us

It can be difficult to go over the Lean Six Sigma History, as many believe everything originated in Japan with the Kaizen methodology. However, this is quite off, and you should understand that the Kaizen methodology is not what made the foundations of LSS; instead, it is the reason why the methodology we work with was made. At Lean Six Sigma Curriculum for Toledo High School Students of Ohio, we have been working with LSS for decades, and we understand where it comes from and how Kaizen is involved in all this.

You must first understand that this methodology was designed to help companies prioritize customers and improve earnings. It incorporated principles and structures of two major methodologies: Six Sigma and Lean.

The methodology can reduce costs and eliminate waste if done correctly. It is also important to keep quality and performance in mind throughout the process.

It is more than just a combination. Lean Six Sigma integrates the best of Lean and Six Sigma while also adding more principles that address the lacking points of the two individual methods.

Many believe LSS is Japanese because of the Kaizen method and other philosophies developed in Japan since they helped improve Japan’s industries, particularly manufacturing. It also encouraged thinking about the customer and reduced costs. This resulted in increased production and manufacturing and made Japanese industries to be at the top back in the 80s when American industries were falling behind in comparison.

When Was LSS Created?

To understand where LSS comes from, you must understand that Six Sigma and Lean are both well-known concepts that have been around for many decades. Toyota invented lean in the 40s to reduce non-value-adding activities.

Lean believes that employees should actively participate in organizational change to foster excellence and reduce all waste and processes that aren’t worthy.

Lean believes that continuous learning and improvement are two of the most important pillars to ensure everyone is happy, gets the desired results, and maximizes all resources.

This Lean methodology was founded by Toyota Production Systems (TPS), which Japanese Taiichi Ohno founded. Lean was born using Henry Ford’s innovations and Business Process Redesign specifically.

To give you a closer overview of Lean, this is how the methodology works—put simply—:

- Lean begins with understanding the customer’s added value and how to satisfy it.

- Both the value stream and how processes are performed are mapped.

- The previous step allows you to identify and increase your waste flow. The data is then collected to reveal waste and share. This is the first step toward improving the process.

- Next, it is time that you work with the process of setting up the system in a way that customers can request it and it delivers it to them when they are ready.

- Employees will be able to identify areas where they can improve and work together to fix them. This allows for process-wide thinking. This allows everyone to be focused on the customer’s requirements efficiently and effectively.

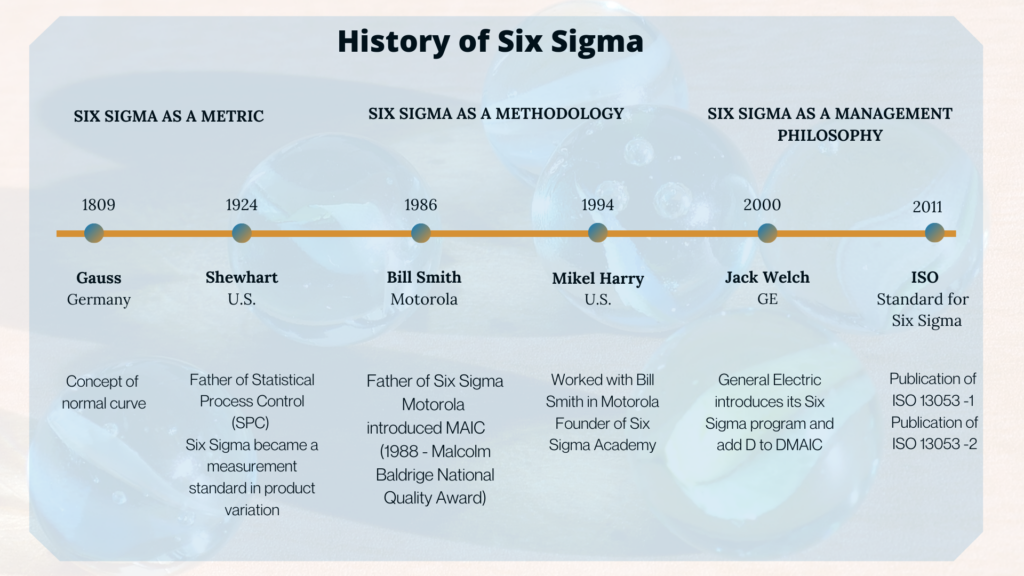

Lean is based on all the above, but Six Sigma is more data-driven. Motorola developed the method, and General Electric used it successfully in the 80s.

Six Sigma’s structure is centered around the DMAIC option. Define, Measure, Analyze, Improve, Control. This is helpful for manufacturing but also in other industries to automate processes and reduce waste while improving cycles and processes.

In addition, 6 Sigma originated just a few years earlier than LSS, as the latter is more from the late 80s.

With this in mind, LSS was an answer to the way Japanese companies were innovating, improving, and getting better quality products while still satisfying their customers.

Since Lean and 6 Sigma still had some elements lacking, LSS brought them together and added more elements to achieve better results.

LSS Takes Over the USA

Essentially, LSS was designed to allow American companies to compete with Japanese manufacturers. It is a combination of both existing methods, as we mentioned earlier. As you can see, it was created in the United States before any other country decided to integrate it.

This addition provided valuable insights and improved efficiency for the industry. This combination allowed for growth without compromising customer satisfaction either.

Lean Six Sigma was mostly for manufacturing when it began. Still, today, it is used in more industries, and practitioners even achieve better results in their personal projects while following the method’s structure adopted from Six Sigma.

Schools and educational institutions can create systems that are more efficient and simpler to use as well, and LSS can be taught to students, which can improve their job prospects and career opportunities.

There are many benefits to being involved in Lean Six Sigma, which can increase your professional as well as personal opportunities. Contact Lean Six Sigma Curriculum Pros of Toledo if you’re interested in learning more or getting involved in this industry.